|

So what exactly is duty cycle transient?

There are 3 types of thermal modeling calculations:

steady state, simple transient,

and duty cycle transient. Steady state

calculations provide temperature for a unit which is fully warmed up and

has reached equilibrium temperatures. For a simple transient analysis,

an electronic unit is initially at some starting temperature. Power is

turned on and the unit heats up to reach the steady state temperature.

During the simple transient calculation, wattages and ambient temperatures

are held constant.

|

Duty cycle transient (repeating pattern)

Duty cycle transient (repeating pattern)

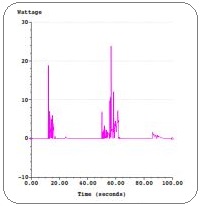

Random power duty cycle

Random power duty cycle

| |

For many real world problems, however, simple transient is just not

enough. Duty cycle transient is required. As an example, think of

antilock brake (ABS) circuitry in an automobile. When the driver of a

car hits the brake pedal, the control circuitry pulses the brakes. This

causes heat dissipation to rise and fall rapidly. To predict temperatures

for an ABS module, wattages must be allowed to vary during the transient

analysis. In other words, duty cycle transient is an absolute necessity.

There are many other real world problems where duty cycle capability is

essential. Frequently, both ambient temperature and heat dissipation

varies with time.

As most engineers know, duty cycle problems vary widely. Some problems

deal with straightforward repeating patterns, such as combinations of

square waves and pulses (see top curve on left). On the other extreme,

as shown in the lower curve, there are "random power" duty cycles.

With random power, the power variation is not easily described and there

are thousands, if not millions, of data points.

Some duty cycle problems have a duration of several hours,

while duty cycles based on millisecond pulses are also common. All in all,

there's a huge variation in duty cycle problems. Nonetheless, Sauna provides

you with the tools to deal with all of these duty cycle configurations.

Defining duty cycles is easy with Sauna

With Sauna, a basic duty cycle problem can be defined in just a

minute or two. To define a square wave, for example, it's a simple

matter of using Sauna's menus to define the first pulse, define the

second pulse, and enter the total number of cycles. Just as soon as

the duty cycle is defined, it can be graphed within Sauna to verify

that no errors were made. It's a simple, no-stress method.

For more complex repeating waveforms, Sauna provides a powerful

scripting language. With just a few lines of script, you can easily

define loops, ramps, and other duty cycle variations (see figures on

right). Even though the scripting language is easily learned,

you can effectively model some very complex configurations.

Finally, there are random power duty cycles. For this case, there

are no repeating patterns. Typically, the time/power characteristics

are measured in the field, or perhaps generated by a simulation

program. To handle these problems, Sauna allows for spreadsheet

definition of power (tab-separated or comma-separated). If required,

you can

have more than one million individual power steps.

Of course,

a large model with a highly complex random power profile can take quite

a while to calculate. Simplification tools are essential.

With Sauna you can easily simplify an entire randorm power profile,

or you can simplify just a portion. With this approach, you can obtain

results in minutes, rather than hours.

Duty cycles can be applied for either wattage or boundary temperature.

There are no limits to the total number of different duty cycles in the

model. It's not even necessary to provide duty cycles which share the

same time coordinates. Sauna automatically interpolates to add the

necessary time coordinates and values. Sauna also incorporates an

integrated standby capability so that a duty cycle problem can be

started with a steady state analysis. Sauna provides a truly

comprehensive set of duty cycle tools.

Calculating temperatures

Temperature calculation is another challenge. After all, no engineer

wants to wait hours for results. Sauna, always known for

rapid calculation times, has a highly advanced temperature solver which

has been specially optimized for duty cycle calculations. For many

problems, the temperature calculation will take just a few minutes. You

should expect that Sauna will be substantially quicker than either FEA

(finite element analysis) or CFD (computational fluid dynamics) software.

As always, Sauna automatically calculates convection and radiation heat

transfer coefficients. Since these heat transfer coefficients are

temperature-dependent, it is important to recalculate these parameters

during the course of a duty cycle analysis. Sauna does this for you,

quickly and efficiently.

Viewing results and modifying the model

Once the temperature calculation is complete, the engineer needs to

review results to identify maximum temperatures. After all, for duty

cycle transient the maximum temperature can occur at any point in the

cycle. To provide a complete view of temperature data, Sauna

incorporates a comprehensive plotting utility. "Temperature vs. time"

data can be plotted on the screen, printed, or exported to other

applications (Postscript, BMP, or spreadsheet format). Temperature

charts can also be prepared. Sauna provides all the tools you need

to interpret and document the results of the duty cycle calculation.

Many times, a duty cycle temperature calculation will indicate that

temperatures are not at acceptable levels. If this is the case,

Sauna has many tools for what-if studies. It's a very simple matter

to modify fins, relocate heat sources, change board copper content

and much more. With all these powerful tools, Sauna is the ideal

tool for duty cycle transient.

|